OUR PRODUCTION

ALMADA LABEL collections have been designed and produced in collaboration with our factories located in Portugal, Italy, Inner Mongolia and China. We are focused on creating long-lasting high-quality pieces that are responsibly sourced and ethically produced. We are committed to transparency, clarity and sharing information openly with our customers, which is why we want to open the doors to our factories and give you an insight into our manufacturing process.

To create an ALMADA LABEL knitted garment, several different steps have to be taken. Follow along below as we take you with us to one of our factories & show you how our products are done step by step, from farm to finished garment.

FABRIC SOURCING

The first step in our design process is fabric sourcing where we choose the materials we want to work with for a particular design. We search through different materials and color charts to find the perfect match for our design.

We only invest in the finest materials with the best possible qualities since the materials we choose hugely impact the quality and the lifespan of our pieces. It is also important to us to find a material that we can work with not only for one piece but for other designs as well.

COLLECTION OF THE RAW MATERIALS

The raw material is the starting point of a garment. The creation of our knitted garments starts from the wool sheep/cashmere goat farm where our precious raw materials are collected.

Animal welfare and ethical practices like 'non-mulesing' are of great importance to us and we only work with suppliers that follow these practices.

COLORING & CONSTRUCTION OF THE YARN

When the raw material has been collected it is then dyed into our desired colour at the farm. Darker colors require often a stronger dyeing process than lighter shades that are closer to the natural colour of the undyed yarn. The wool is washed and dried before the spinning of the wool to the yarn can start.

In this process the coloured wool is twisted and spun into the yarn that later on is being used to knit the garments. A spinning machine stretches, spins and twists the wool fibers together into strong and beautiful high quality yarn. The ready spun yarn is then wrapped around cardboard cones and packed into boxes ready to be shipped to our factories for the next step in the production chain.

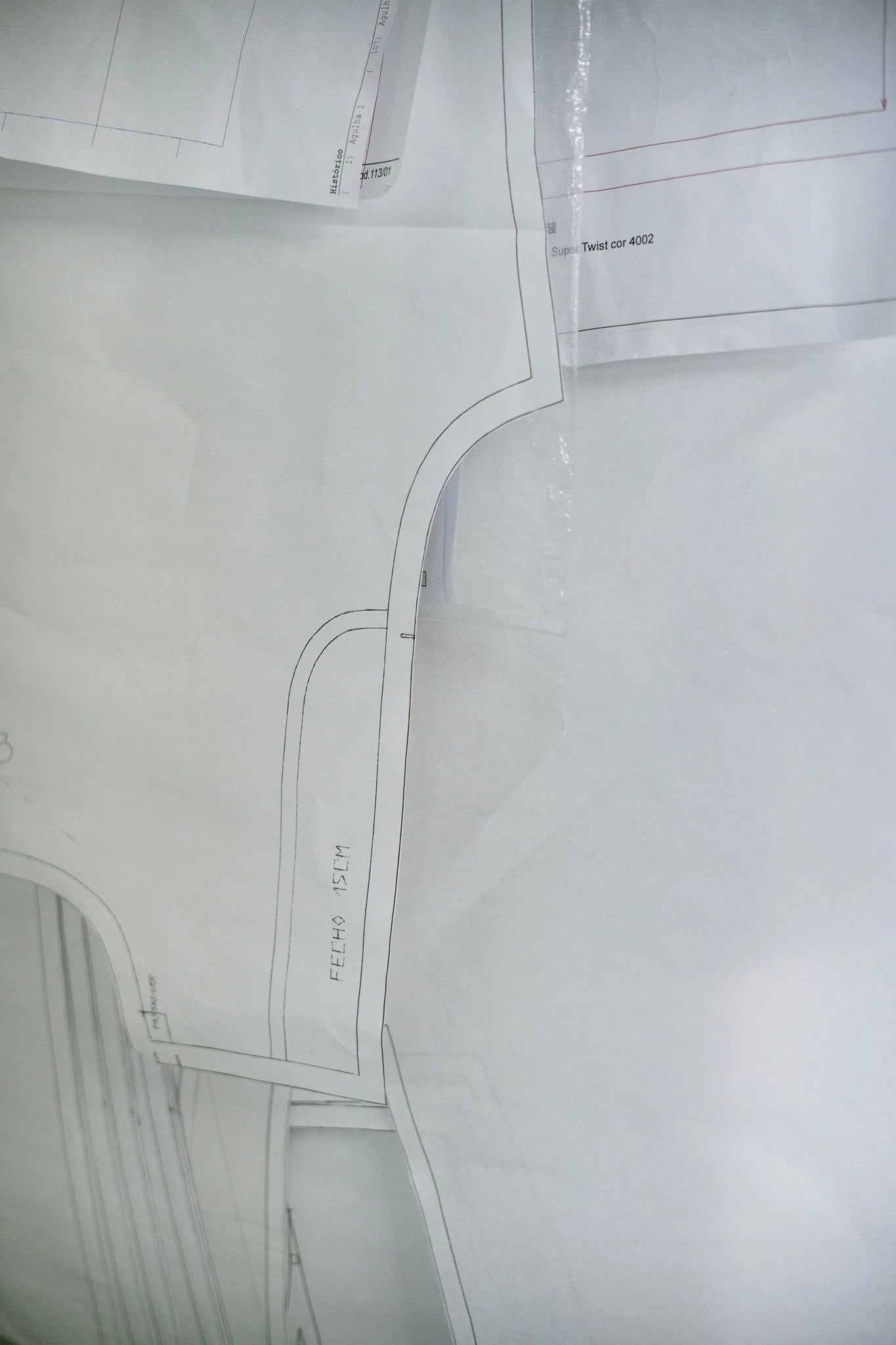

PATTERNS

The pattern of each garment acts as a road map to our factories on how the ready garment should be in shape and size. It is created separately for each design and size in collaboration with our designer and the factory. Every little measurement, loop and detail of the garment is then entered into a specialized knitting pattern computer software that digitally creates the pattern for the knitting machine.

KNITTING & LINKING

The knitting process takes place in our factories when the yarn has arrived. The yarn for our pieces is always knitted into panels first. The individual parts of the garment such as sleeves, front and back body pieces are being created separately by a knitting machine before they are linked together to become whole garments.

By linking, the knitted panel pieces are attached so that they become whole garments. Linking is always done manually and it’s the part of the process that takes the most time.

The neck label with our ALMADA LABEL logo is being sewed on by hand to the ready garment.

WASHING & STEAMING

The surface of a knitted wool/cashmere piece needs to get washed for one last time to get the soft and smooth surface and hand feel. Different colours and yarns react differently in the washing process thus the correct detergents must be used at the correct temperatures and lengths of the washing programs. Otherwise, the garment might get ruined.

The garment is being steamed not just to get the final finishing touch on the smooth surface but to also achieve the final shape and to check that all the measurements are as they should be. We have created size charts with exact dimensions for each design and size, and these are checked on the steam board for every garment. After this, the garment gets to dry and then we have our final knitted garment ready in its’ desiredsilhouette and measurements.

PACKING

The last step before the ready garment is being shipped to our warehouse is packaging. All the garments are being neatly folded and individually packed in to small breathable bags that are then placed in carboard boxes ready to get shipped to our warehouse.